In any precision electronic device, from your smartphone to a server's 10G network card, a key foundational board is indispensable — the PCB (Printed Circuit Board). It is often referred to as the "skeleton" of an electronic product because all chips, capacitors, resistors, and other components must be soldered onto it to work together. However, this definition barely scratches the surface of its importance. The design and manufacturing quality of a PCB actually combines the roles of a product's "central nervous system" and "cooling system", directly determining the system’s performance ceiling, signal transmission efficiency, and even its overall lifespan.

1. Signal Integrity: The Lifeline of High-Speed Data Transmission

In the era of low-speed electronics, the PCB’s main job was merely to establish circuit continuity. But today, with high-speed interfaces like PCIe 4.0/5.0, DDR5 memory, and 10G networks becoming mainstream, the role of the PCB has fundamentally changed. Here, a key concept must be introduced: Signal Integrity (SI).

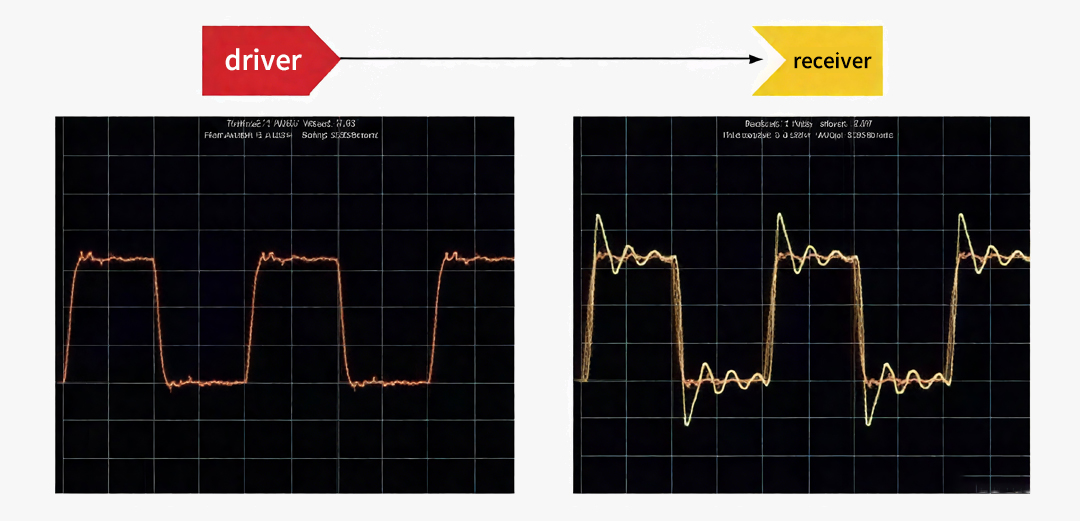

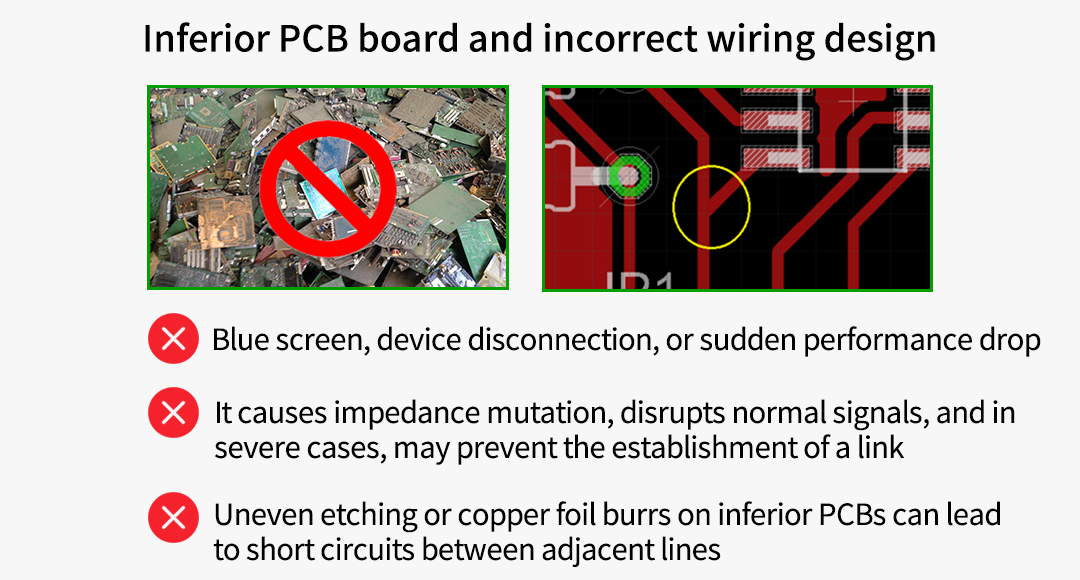

High-speed digital signals are essentially weak electromagnetic waves. When transmitted on the PCB’s copper traces, they are highly susceptible to physical factors that can cause distortion, reflection, and attenuation. Poor PCB design can directly lead to:

Timing errors and data corruption: In high-speed communication, signals must arrive precisely within nanoseconds or even picoseconds. If a set of related traces (e.g., differential pairs in PCIe lanes) have different lengths, signal delays occur, and the receiver may fail to correctly interpret the data, resulting in blue screens, disconnections, or major performance drops.

Impedance mismatch and signal reflection: PCB traces need precise characteristic impedance (usually 50 ohms) to match the interface of components. Any error in trace width, corner, or via design can cause impedance discontinuity, making the signal reflect like light hitting a mirror, disrupting the normal signal and potentially preventing link establishment.

High-end products often adopt complex and costly PCB designs precisely to ensure smooth signal “journeys” through accurate trace length matching, smooth corner routing, and strict impedance control.

2. Heat Dissipation: The Key to Staying “Cool” Under Load

“Higher performance, greater heat” is a general rule for electronics. High-performance chips such as CPUs, GPUs, and FPGAs generate massive heat when fully loaded. If this heat isn't efficiently dissipated, it can cause throttling or even permanent damage.

The PCB itself plays a critical role in system heat dissipation. Its thermal capabilities are mainly reflected in:

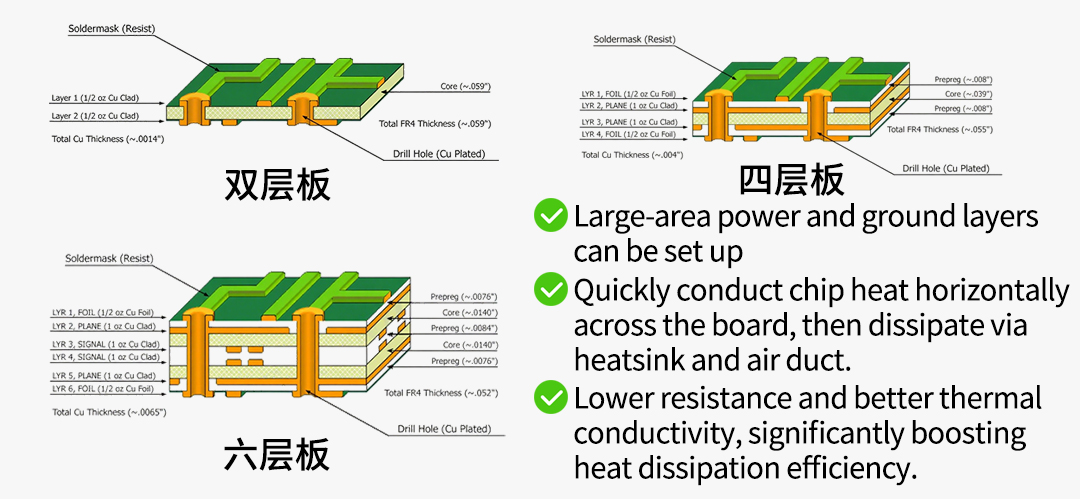

Multilayer PCBs with large copper planes: Compared to cheap 2-layer boards, high-end devices typically use 4, 6, or more layers. The extra layers not only provide more routing space but also allow for large power and ground planes. These continuous copper planes act like giant heat sinks, quickly spreading the heat across the board and into external coolers or airflow systems.

Copper thickness and thermal vias: The thickness of the copper (measured in ounces, oz) is crucial. Thicker copper means lower resistance and better heat conduction. In addition, densely packed thermal vias beneath chips help transfer heat vertically from the top layer to other layers or the PCB’s backside, greatly enhancing thermal performance.

A PCB with poor thermal design can become the system bottleneck, even if paired with top-tier chips and heatsinks.

3. EMI Resistance: The Foundation of Electromagnetic Compatibility

Electronic devices emit electromagnetic waves during operation, causing electromagnetic interference (EMI), and are also vulnerable to EMI from other nearby devices. Strong EMI resistance is essential for stable operation.

PCB layout and grounding design are key to its EMI resistance:

Reasonable component layout: Separate high-speed, analog, and power regions to prevent sensitive signals from being interfered with by high-power components.

Complete ground planes: Multilayer boards offer solid ground layers that act as effective shields, absorbing internal interference and providing stable, low-impedance return paths for signals, greatly reducing EMI radiation. In contrast, 2-layer boards struggle to achieve ideal shielding due to layout and grounding constraints.

4. Mechanical Strength and Reliability: The Guarantee of Durability

Besides electrical performance, a PCB must have sufficient physical strength. As component density increases and large heatsinks become common, the PCB must endure high stress and thermal cycling.

Flexural resistance: A well-built, thick PCB resists bending during installation of large GPUs, CPU coolers, or transportation, preventing solder cracks or component damage.

Heat resistance: During soldering (wave or reflow) and long-term use, the PCB material must withstand high temperatures without delamination or bubbling. High-quality base materials (like high Tg FR-4) perform better here, ensuring reliability in harsh environments.

Conclusion: The Hidden Divider Between Product Tiers

In summary, the PCB is far more than a simple supporting platform. It is a complex system made of active and passive components, and its design and quality deeply impact every aspect of a product.

Low-cost products, like entry-level motherboards or expansion cards, may use 2-layer PCBs. While functional, they struggle under heavy load or in complex EMI environments.

High-end devices, such as server motherboards, GPUs, and 10G NICs, commonly use 4, 6, or more layers. Though costlier to make, they offer excellent signal integrity, thermal performance, and EMI resistance — the true foundation for stable, full-throttle operation under extreme conditions.

So next time you compare two electronic products with similar specs but wildly different prices, remember — the difference may lie in the unseen but vital PCB.